WHAT IS INDUSTRY 4.0? INDUSTRY 4.0 INDUSTRIAL REVOLUTIONS

The definition of Industry 4.0 was answered with a technology fair held in Germany in 2011. The 4.0 zero industrial revolution, named after the previous three industrial breakthroughs, brought many innovations. The 4.0 revolution actually started in England in the 18th century, about hundreds of years ago, with three historical industrial breakthroughs. The process, which started with water and steam machines in the first industrial revolution, led to the beginning of a different era in the world with the introduction of electricity. The industrial revolution brought about four revolutions after this process.

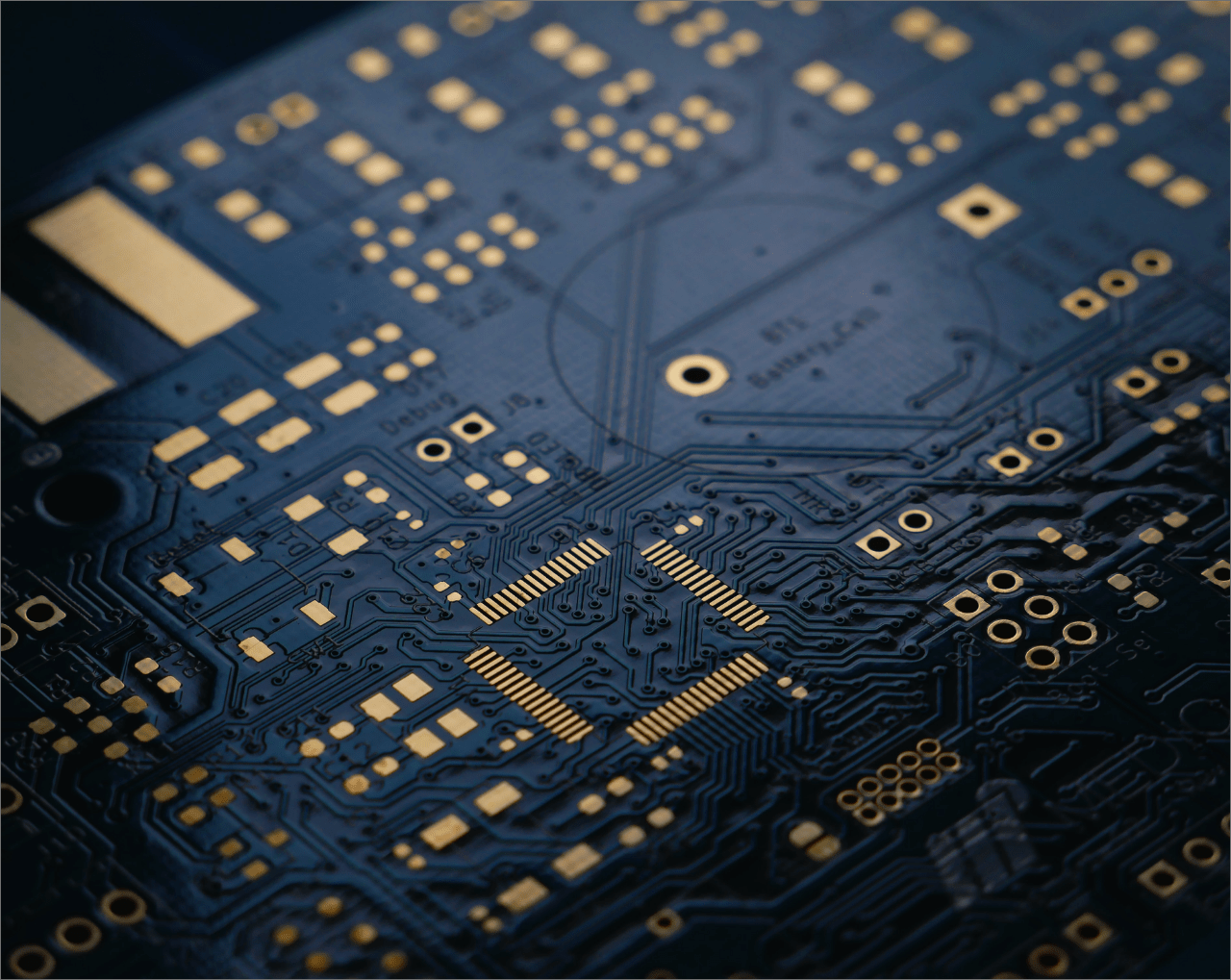

In the 1970’s, in the industrial sector, where different methods were discussed, the age of automation became indispensable for production tools for forty years. During this period, mechanics and electronics merged under a single name. The hybrid model of mechanics and electricity has revealed a new technology, automation. Automation has left its place to digitalization and robot technologies with mechanical and electronic models. The automation revolution, which lasted about forty years, reached a different point with the arrival of the internet in the early 2000s. With the introduction of the Internet, the 4.0 industrial age has begun.

Industry 4.0 Innovation In Technology

The most common question these days is "What is Industry 4.0?" The beginning of the 4.0 era continued with the widespread use of the internet in production. The technology developing in the age of 4.0 has enabled new developments to occur in the production era with smart machines, advanced operating systems and artificial intelligence. These developments, as in every period, developed the industry sector the most. Artificial intelligence has been one of the most important tools of this forward leap in the industry. With artificial intelligence, technical experience, speed and efficiency, and smart machines, production increased exponentially, and new sectors and markets were opened.

With the 4.0 revolution, factories have reached high production capacities with less fuel, labor and energy. This leap in production attracted the attention of manufacturers. Businesses that benefited greatly from time, energy and profit with 4.0 increased their annual turnover to the same extent. This situation led to the growth of businesses and enabled them to have a say in the world market.

What Does Industry 4.0 Aim For?

What is aimed with Industry 4.0 is to maximize production capability. It is aimed to shorten the time between supply and demand and to enable consumers to reach the products more easily. Industrial companies working with consumer index in high production aim to get rid of the environment and the world from some unnecessary factors.

Experiences With Industry 4.0?

Environmentally friendly production lines with a sufficient number of qualified work force began to be preferred. This savings realized in many areas ensured that a significant amount of money was not lost during the production phase. As money was saved during production, important developments were experienced in many areas such as social welfare level and income equality.

Lanner Electronics: https://www.lannerinc.com